|

| |

|

| |

|

| |

| |

| |

Basic rules of the clean air

|

|

| |

| |

| |

There are a great variety of clean room systems and additive machines. Here it shows the most basic mode. For the process of the concrete operation, we must consider the spontaneous dust in space and the dust brought by operators. |

|

|

| |

|

|

|

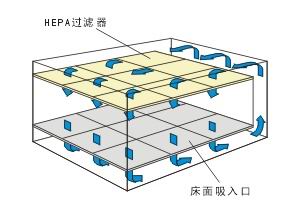

1.Vertical laminar flow |

|

| The whole ceiling joist has HEPA filters. The air blows on bed vertically, then exhaust the air roundly and cycle it. The clean air is blown out in the shortest distances by this mode, so the cleanliness is very high. The cleanliness of the headwaters, which doesn't blow out dust and bacteria, could reach class 100. It blows out air roundly, so the whole clean room can reach the same cleanliness. |

| |

Class |

The numbers of changing air (number/h) |

Air speed (m/S) |

100 |

200-600 |

0.25-0.3 |

|

| |

|

| |

|

|

|

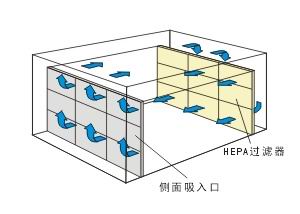

2.Horizontal laminar flow |

|

| One flank of the clean room all has HEPA filters and it is ejiction opening. The air blows on the other flank, then exhaust the air and cycle it. The cleanliness around the ejiction opening and the vent is heterogeneous by this mode. Only around of the ejiction opening, the cleanliness reaches class 100. The cost of the horizontal laminar flow is the most expensive of the three modes. |

| |

Class |

The numbers of changing air (number/h) |

Air speed (m/S) |

100-1000 |

100-600 |

0.45-0.6 |

|

| |

|

| |

|

|

|

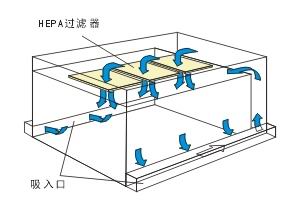

3.Turbulent flow |

|

| One flank of the clean room has HEPA filters and it is ejiction opening. At one flank near the bed surface, cycle it. Generally, it is placed at the ejiction opening of the pipeline adjusting air. The cost of this mode is cheaper. But the airflow is in disorder, so the cleanliness is heterogeneous and limited between class 10000~100000. |

| |

Class |

The numbers of changing air (number/h) |

Air speed (m/S) |

10000-1000000 |

20-60 |

---- |

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

ISO9001£º2000. CCC. CE CERTIFIED AND MD REGISTERED |

===================================================================================================================================== |

| |

ADD: 31 Qihong road, SIP Suzhou |

|

TEL:0512£62522538 |

| |

ZIP:215006 |

|

FAX:0512£62522938 |

| |

WEB:http://www.baishen.com |

|

E-mail:clean@baishen.com |

|

===================================================================================================================================== |

Copyright (C) 2005 |

SUZHOU BAISHEN TECHNOLOGY CO., LTD |